Exceptional Camshaft Manufacturing Companies: Leading the Diesel Engine Parts Market

Understanding Camshaft Manufacturing Companies

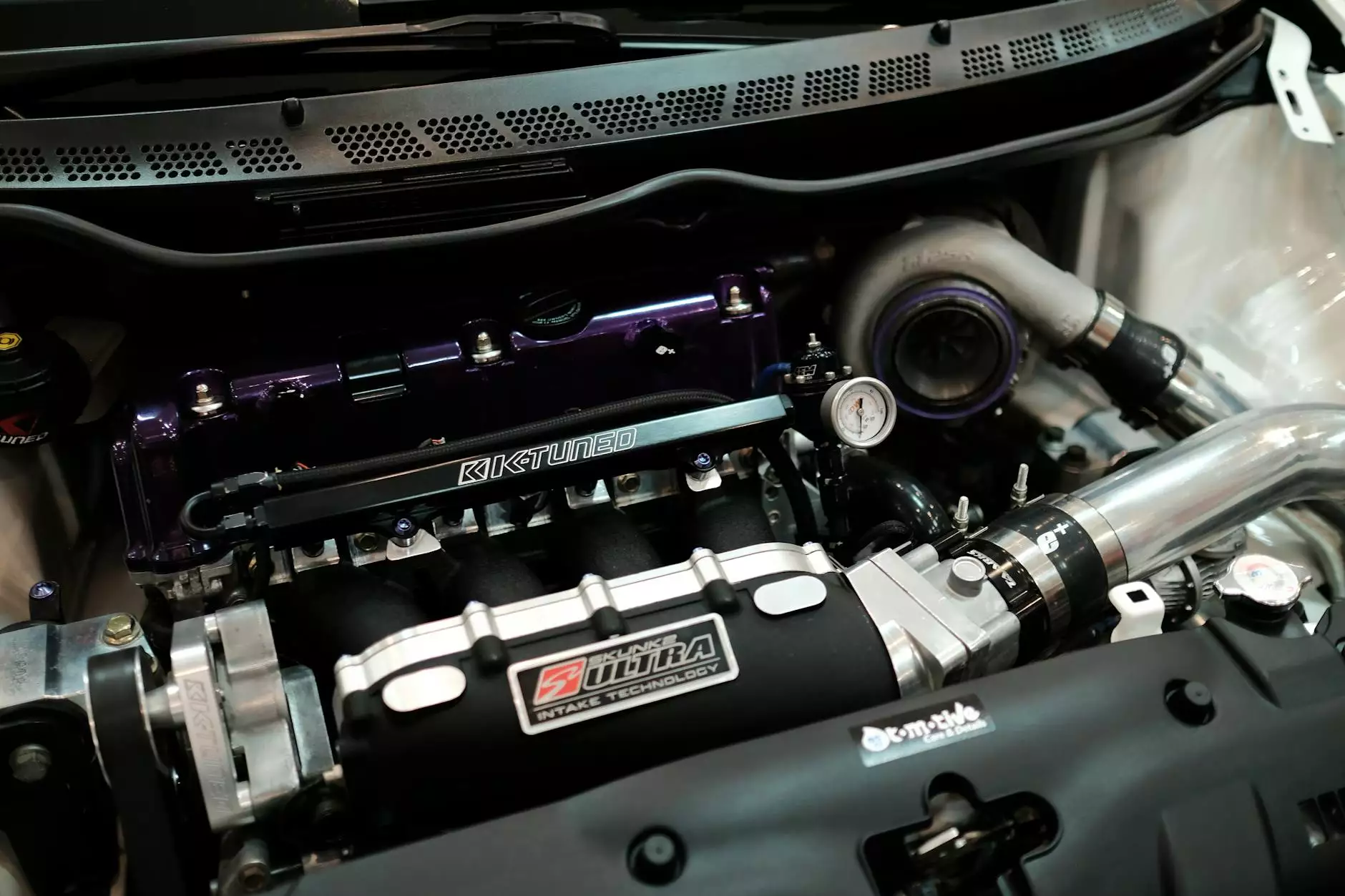

Camshaft manufacturing companies play a crucial role in the automotive and heavy-duty machinery industries. These businesses specialize in producing camshafts, which are vital components in internal combustion engines.

The camshaft controls the timing of the opening and closing of the engine's valves, impacting engine performance, efficiency, and emissions. With the growing demand for diesel engine parts due to the reliability and efficiency of diesel engines in various applications, the significance of competent camshaft manufacturers has never been higher.

The Importance of Camshafts in Diesel Engines

In diesel engines, the camshaft serves several functions, including:

- Regulating Valve Timing: It ensures that intake and exhaust valves open and close precisely during the engine cycle.

- Influencing Engine Performance: Optimal camshaft design enhances airflow into the cylinders, increasing power output and efficiency.

- Reducing Emissions: Advanced camshaft designs help in achieving cleaner combustion, resulting in lower emissions.

These functions underscore the importance of sourcing camshafts from reputable camshaft manufacturing companies. Quality camshafts can significantly impact an engine's performance and longevity.

Top Camshaft Manufacturing Companies to Consider

As the demand for quality diesel engine parts increases, several companies have distinguished themselves in the field of camshaft manufacturing. Here are a few of the top players in the industry:

1. International Truck and Engine Corporation

Known for its commitment to excellence, International Truck and Engine Corporation offers a comprehensive range of camshafts tailored for diesel applications. Their rigorous testing and quality assurance processes make them a preferred choice among engine manufacturers.

2. Cummins Inc.

Cummins is synonymous with reliable diesel engines. Their camshaft manufacturing processes utilize state-of-the-art technology, ensuring high precision and durability. They provide a range of camshafts compatible with various engine models.

3. Caterpillar Inc.

Caterpillar, a leader in heavy machinery, also offers specialized camshaft solutions. Their dedication to innovation and sustainability makes their products ideal for modern diesel engines.

4. Bosch

Bosch is a name that resonates within the automotive sector. Their camshaft products are known for high performance and their contribution to reducing fuel consumption and emissions.

5. Mahle GmbH

Mahle is a prominent player in the global automotive component market, providing high-quality camshafts that meet diverse engine specifications.

Quality Standards in Camshaft Production

The excellence of camshaft manufacturing companies is often measured by their adherence to quality standards. To ensure the best performance, manufacturers must comply with international standards such as ISO 9001 and IATF 16949. These standards guarantee that the products meet stringent quality requirements throughout the manufacturing process.

Additionally, many manufacturing companies invest in advanced manufacturing technology, including:

- CNC Machining: Computer Numerical Control machining allows for high precision and repeatability in camshaft production.

- Heat Treatment: This process enhances the durability and wear resistance of camshafts, ensuring they perform under high-stress conditions.

- Surface Finish Technology: Optimal surface finishes reduce friction, which is pivotal for engine efficiency and longevity.

By adhering to these standards and employing cutting-edge technology, camshaft manufacturing companies can provide high-quality products that meet and exceed customer expectations.

The Future of Camshaft Manufacturing

As the automotive industry evolves, so too does the technology and methods used in camshaft manufacturing. With the rise of electric vehicles and hybrid technology, camshaft manufacturers are adapting their products to align with industry trends.

Some anticipated trends include:

- Increased Use of Lightweight Materials: To meet fuel efficiency standards, manufacturers are exploring advanced materials that reduce weight while maintaining durability.

- Smart Manufacturing: The integration of AI and IoT technologies in production processes is anticipated to streamline operations, resulting in improved efficiency and cost savings.

- Custom Camshaft Solutions: Companies are likely to push for more customization in camshaft design to meet specific performance requirements of diesel engines.

This adaptability will ensure that camshaft manufacturing companies continue to be pivotal in the industry, meeting the ever-changing demands of the market.

The Role of Spare Parts Suppliers

Alongside manufacturing companies, spare parts suppliers play an essential role in the lifecycle of diesel engines. They augment the supply chain by distributing high-quality camshafts and other components to repair shops and engine builders.

Critical functions of spare parts suppliers include:

- Inventory Management: Maintaining an adequate stock of camshaft products to meet demand in a timely manner.

- Quality Assurance: Ensuring that all products sourced from manufacturers meet strict quality criteria before distribution.

- Customer Support: Offering technical support and guidance regarding product selection and installation procedures.

With the growth of online marketplaces, spare parts suppliers have expanded their reach, making it easier for customers to access quality diesel engine parts and enhancing overall service delivery.

Conclusion

In conclusion, camshaft manufacturing companies are indispensable players in the realm of diesel engine parts. Their commitment to quality, innovation, and adaptation to industry trends positions them at the forefront of the market. Companies like Cummins, Caterpillar, and Bosch exemplify the standards of excellence in camshaft production.

As the industry continues to evolve, both manufacturers and spare parts suppliers will need to maintain a focus on quality and sustainability. By doing so, they will ensure that diesel engines remain reliable and efficient, satisfying the needs of consumers and industries alike.

For those seeking high-quality diesel engine parts and exceptional camshaft solutions, visit client-diesel.com for your needs.